+91-9727776724

changodarmetals@gmail.com

Welcome to our Website

Changodar Metals Private Limited is a distinguished and well-experienced manufacturer, exporter and supplier of aluminum slugs and strips to several industrial customers. Established in 2004, we are offering metallic slugs and strips that are durable and strong. We have been offering our products for more than a decade and offering them at magnificent quality at attractive prices. We understand the needs of various industries and offer them quality products with comprehensive customer satisfaction. We are dispatching our products within the agreed time. Quality Assurance Our products are popularly used in the cables, and composite pipes industry. Our products are strong, durable, and can be easily customized as per the needs of the customers. We are offering aluminum slugs, strips, sheets, and circles.

Glimpse of Our Company

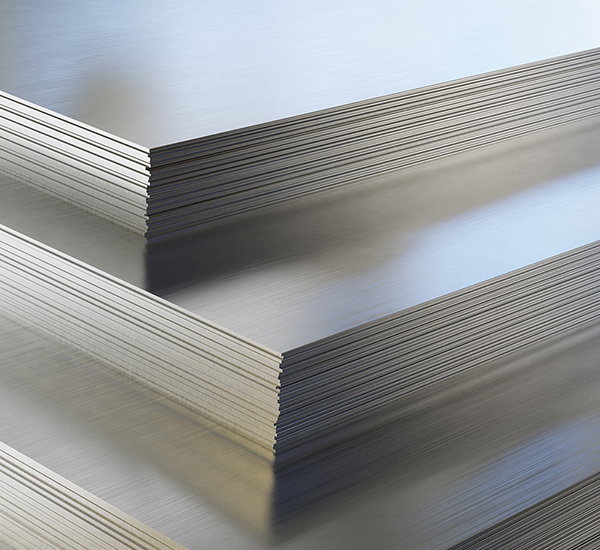

Aluminium Products

Process

Testimonials